Essential Guide to Paper Mill Maintenance: Preventing Costly Shutdowns

Oct 1

2 min read

0

7

0

Every minute of downtime in a paper mill can cost thousands of dollars in lost production. With over 30 years of experience serving paper mills across America, A&W Devices understands the critical challenges maintenance teams face in keeping these complex operations running smoothly.

Key Takeaways:

Proactive maintenance can prevent emergency shutdowns

Proper tool selection reduces repair time by up to 60%

Safety-compliant solutions minimize workplace incidents

Strategic maintenance planning saves mills an average of $50,000 annually

Common Paper Mill Maintenance Challenges

Paper mills face unique maintenance hurdles that require specialized solutions. The combination of high temperatures, caustic chemicals, and continuous operation creates particularly demanding conditions for equipment and maintenance teams.

Critical Areas Requiring Regular Maintenance:

Digesters and pressure vessels

Stock preparation systems

Steam systems and boilers

Recovery boilers

Paper machine rolls

Essential Maintenance Solutions

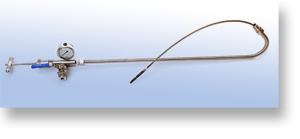

Maintaining clear stock lines is crucial for continuous operation. When blockages occur, our specialized Rod Out tools with various angle options (Straight, 60°, 90°) allow maintenance teams to clear obstructions without system shutdown. This approach has helped mills maintain 98% operational efficiency.

Flange Management Proper flange maintenance prevents costly leaks and ensures environmental compliance. The Side Winder Flange Spreader enables safe, efficient flange separation without damaging expensive components. This tool has become standard equipment in leading paper mills nationwide.

Cost-Effective Maintenance Strategies

Implementing a comprehensive maintenance program:

Schedule regular inspections

Document equipment performance

Train teams on proper tool usage

Maintain emergency repair equipment

Partner with reliable tool suppliers

Choose maintenance tools that offer:

Chemical resistance

High-temperature capability

Precision control

Safety compliance

Durability in harsh conditions

Impact on Production Efficiency

Mills using proper maintenance tools and procedures report:

30% reduction in emergency repairs

25% decrease in maintenance costs

15% improvement in operational efficiency

40% reduction in safety incidents

Don't wait for an emergency to upgrade your maintenance toolkit. A&W Devices offers specialized solutions designed specifically for paper mill applications. Our technical team can help you select the right tools for your specific needs.

Contact us at 925-516-4204 for a consultation or visit our product page to explore our paper mill maintenance solutions.