Valero Benicia Refinery Closure: Impact on California's Industrial Landscape and Maintenance Planning

Jul 31

2 min read

0

7

0

Key Takeaways:

Valero's Benicia closure reflects broader challenges in California's refining sector

Maintenance teams should prepare for potential supply chain impacts

Preventive maintenance becomes more critical with fewer operational refineries

Cost implications may affect maintenance budgets industry-wide

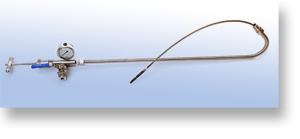

The recent announcement of Valero Energy Corp's planned closure of its Benicia refinery marks a significant shift in California's industrial landscape. As maintenance experts serving refineries for over 30 years, A&W Devices recognizes the broader implications this closure has for our industry partners.

Understanding the Closure The Benicia refinery, which processes approximately 145,000 barrels per day, faces closure due to several factors:

Stringent California environmental regulations

Rising operational costs

Complex compliance requirements

Aging infrastructure challenges

Impact on Regional Gas Prices This closure could significantly affect California's fuel market:

Reduced in-state refining capacity by approximately 8%

Potential increase in fuel import dependency

Higher transportation costs for refined products

Market volatility during maintenance periods at other refineries

Maintenance Implications for Remaining Facilities For maintenance teams at operational refineries, this closure emphasizes several critical points:

Increased Production Pressure

Remaining facilities may need to optimize output

Enhanced focus on preventing unplanned shutdowns

Critical need for efficient maintenance solutions

Greater emphasis on quick emergency repairs

Preventive Maintenance Becomes Critical With fewer operational refineries, preventing shutdowns becomes more crucial than ever. Facilities should:

Implement robust preventive maintenance schedules

Maintain adequate spare parts inventory

Invest in reliable maintenance tools and equipment

Train teams on emergency repair procedures

Planning for the Future Maintenance teams should prepare for:

Increased operational demands

Potential budget adjustments

Enhanced safety protocols

Supply chain considerations

Industry-Wide Recommendations Based on our experience serving refineries across California, we recommend:

Reviewing current maintenance protocols

Updating emergency response procedures

Investing in reliable maintenance tools

Strengthening preventive maintenance programs

Cost Management Strategies To offset potential budget impacts:

Optimize maintenance schedules

Invest in quality tools that reduce downtime

Consider cost-effective emergency repair solutions

Plan for potential supply chain disruptions

Safety Considerations With increased production pressure, safety remains paramount:

Maintain strict compliance with safety protocols

Ensure proper tool selection for maintenance tasks

Regular team training and updates

Emergency response preparedness

Looking Ahead While the Valero Benicia closure presents challenges, it also emphasizes the importance of efficient maintenance practices. Facilities that prioritize preventive maintenance and invest in quality tools and procedures will be better positioned to handle increased demands.

Need Support? A&W Devices remains committed to supporting California's industrial facilities with reliable maintenance solutions. Contact our team at 925-516-4204 for tool selection to help maintain efficient operations during these industry changes.